Production

All of our printed fabrics are designed and digitally printed on-site at our facility in Durham, North Carolina. Having in-house print capability is critical for a couple reasons:

1. It allows us full control over the process and workflow. Producing the highest-end digital textile prints requires careful attention to detail on everything from base fabric selection/testing, artwork design, color management, equipment maintenance/tuning, and Q/A checks. This is something we take incredible pride in and work to perfect each and every day. For us, in-house print capability is a MUST.

2. It simplifies the supply chain. With in-house print capability, we keep production costs low and lead times short. Fast, simple, and cost-effective.

High-End Digital Printing

Our digital printed fabrics utilize a process called "dye sublimation" to create full-color, high-resolution images on polyester and poly-blend fabrics. When we started developing this process in the summer of 2015, the technique hadn't been widely used on the types of outdoor ripstop and taffeta that we specialize in at RBTR. In some cases, particularly for the lightweight and ultra lightweight fabrics (e.g. 15D and 40D), dye sublimation to our knowledge had never been attempted.

For the next six months, we worked both internally and with industry experts to come up with a system that could reliably produce high-end digital prints on our specialty outdoor fabrics. The result is the print division at RBTR.

Performance

Color Palette - Modern digital printing offers a great amount of flexibility when it comes to color. Unlike screen printed goods, you can reproduce any number or combination of colors in a single print. Truly continuous tones can also be achieved.

Color Brilliance -The dye sublimation print process allows extraordinary color brilliance due to the ink's molecular-level bond with the transparent polyester fibers.

Color Fastness - By nature of the dye sublimation process, ink is permanently bonded to the polyester yarn at a molecular level. That's fancy speak for "it won't come off". This means that our printed fabrics are incredibly color fast. They will resist fading and discoloration even after washing and sun exposure.

Image Resolution - Our high-end digital print method can support image resolution of up to 1440 dpi. This number represents the "Dots Per Inch" in the image/pattern file and is an indicator of image resolution (higher the better).

After the image is printed to fabric, our tests have shown there to be no discernible difference in clarity beyond 300 dpi. Thus, we mandate that any pattern or image we print be at least this resolution. This ensures clean lines and a high-resolution end result for your printed fabric.

Digital vs Screen Printing

Screen printing is a common textile print method that uses a series of drums and molds to transfer ink to fabric. There are a couple drawbacks to screen printing:

1. Limitation on number of colors. Screen printing has an upper limit on the number of colors that can be used in a pattern. Depending on the sophistication of the print setup, this is typically 4-11 colors. In contrast, digital printing has no limit on colors that can be used in print artwork. Gradients, photos, and complex artwork are no problem for digital. Coupled with the latest equipment to produce high-end resolution, the design possibilities are only limited by imagination.

2. Time consuming and costly to setup. With screen printing, molds must be made and processes adapted to reliably run EACH new print. This is both time consuming and costly. With digital printing, we can run a myriad of different designs all in the same day with little to no setup time between.

3. Susceptibility to cracking, fading, and peeling. On a basic level, screen printing creates patterns on fabric by laying down a topical coating of ink in a defined area. This can leave the print susceptible to cracking, fading, and peeling over time. By contrast, dye-sublimation digital printing makes a bond to the polyester yarn at a molecular level. This makes the ink transfer nearly permanent under normal conditions.

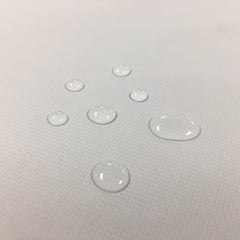

Breathable, uncalendered 1.6 oz polyester ripstop with a DWR (Durable Water Repellent) finish. Natural UV resistance (i.e. resists color fading), low bias stretch under load, and quick drying qualities of polyester.

Breathable, uncalendered 1.6 oz polyester ripstop with a DWR (Durable Water Repellent) finish. Natural UV resistance (i.e. resists color fading), low bias stretch under load, and quick drying qualities of polyester.  The 1.1 oz Silpolyused for OutdoorINK is the third generation of our market first silicone double coated polyester ripstop.

The 1.1 oz Silpolyused for OutdoorINK is the third generation of our market first silicone double coated polyester ripstop.

MEMBRANE 15 is our ultralight 15 denier taffeta polyester. Similar to our MEMBRANE 10 nylon taffeta, MEMBRANE 15 combines breathability, wind/water resistance, and exceptional downproofing with the softest hand feel on the market.

MEMBRANE 15 is our ultralight 15 denier taffeta polyester. Similar to our MEMBRANE 10 nylon taffeta, MEMBRANE 15 combines breathability, wind/water resistance, and exceptional downproofing with the softest hand feel on the market.