Your Cart is Empty

As we continue to push limits on weight and waterproofness with tarp/shelter materials, it's inevitable that some design tweaks will need to be made to keep designs reliable in the field.

About a month ago, I was contacted by a customer seeing some stitch elongation in a rectangular tarp he made with our Membrane Silpoly. We worked through the problem and now have what I think is a good path forward for reliable design, so I wanted to share some of that here.

To give a bit of background, here's a pic of the original problem. This was occurring at both ridgeline tie-outs, but not the ground tie-outs:

Essentially what's happening here is that the reinforcement patch is too thick with not enough stretch to be compatible with the ultralight Membrane silpoly. In other words, under tension the tarp stretches and the reinforcement patch doesn't. With something this thin, that's not good. You need a different approach.

Enter the radial reinforcement. After some back and forth and discussion with others, radial reinforcements using the same material emerged as a potential solution. This does two things:

1. Matches the stretch as much as possible between the reinforcement and the tarp material.

2. Spreads the force out radially from the concentrated stress of the tie-out area. This gives a more even distribution than the standard triangular patch.

This turned out to work very well as a retrofit to the rectangular tarp in question. Radial reinforcements were simply bonded with silnet over top of the original triangular reinforcement patches made from HyperD 300. I've kept in contact with the customer over the past month and the report has been excellent. This method of reinforcement appears to have fixed the problem.

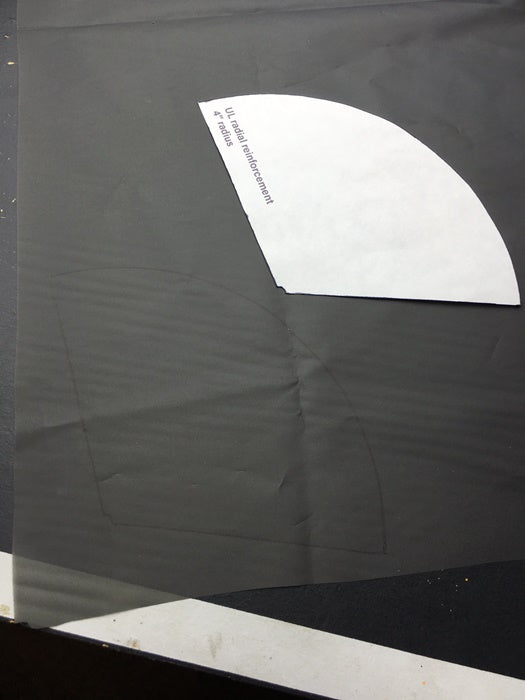

Based on this success, I went off and did some testing of my own. For the reinforcement, I used a 4″ radial patch of Membrane Silpoly (same material used for tarp) bonded with sil-net and unsewn around the perimeter. Here are some pics:

I drew up a little template in lieu of using the coffee can, which makes it simple to cut out patches regardless of the tie-out shape. Applied a thin layer of sil-net to the patch, put down, then let cure overnight with some weight on top. Should be noted that I also cut the reinforcement patches in the approximate same direction as the intended force on the base tarp material to match the stretch (pic 3 above).

For testing, I vertically stitched on the 1/2″ grosgrain tie-out and then tested with 50 lbs. For extra stress, I lifted and dropped the whole thing ~2 ft. Inspected everything after and saw no evidence of stitch elongation at the grosgrain stitching or around the tie-out. Repeated a couple more times with the same result.

I then made a horizontal stitch on the grosgrain tie-out and retested. Still looked good. Some pics of the test setup and close-ups of the tie-out after testing:

I also tested without reinforcements (just 1/2″ gg) under the same conditions. No catastrophic failure, but definitely some stitch elongation near the outermost stitch line on the grosgrain. No bueno. Here’s a pic of that:

Overall the silnet bonded radial reinforcement approach seemed to work very well - both for the finished tarp and in my personal tests. I don’t know if there’s an accurate way to convert wind speed to ~force on a tie-out, but I would think the wind would need to be pretty strong to produce a force that would cause this tie-out to snap.

Of course there’s also the force of tension due to the pitch and that’s going to vary depending on the design or shelter type, but hopefully this gives a good point of reference.

I’m going to rig up a way to add more weight and test to failure so that we have those numbers. I'm also planning to test the strength when pulling in the weft and warp directions (ridgeline/side tie-outs) instead of the bias. I’d like to do this same thing with Membrane silpoly PU4000.

In conclusion, my recommendation is that anyone making a tarp/shelter out of Membrane Silpoly use the same method of reinforcement I've detailed here. If you've already completed your tarp/shelter, just keep an eye on the wear around the tie-outs, especially at the ridgeline. You can always retrofit if need be.

To make this process easier for new builds, we're also going to spin off separate UL tarp kits that include 1/2" hardware, the radial template I used in the testing, and full instructions on how to modify the reinforcement areas.

If you have any questions, please don't hesitate. Thanks!

When you say you “cut the reinforcement patches in the approximate same direction as the intended force on the base tarp material to match the stretch,” do you mean that the warp and woof of the patch are aligned with the warp and woof of the tarp? Or that the warp (or woof) is aligned with the direction of pull from the tie-out?

I know this is an old post, but I hope someone can clarify some things:

Should the reinforcement piece’s grain be running in the same direction as the underlying material (so both pieces have the same amount of stretch), or, say, 45 degrees to each other (in the case of a corner tie-out)?

Would it be OK to insert some webbing (at points where I’d like to create a pocket for a pole mod)? And, if so, in such a case I guess sewing a few curves through ALL materials would be best, right?

Since I am about 70, shake like a leaf, not to mention my poor vision, I plan to see what my semiretired seamstress would charge me just to do the ridge line. I can glue on the reinforcement patches and sew the pull out connections myself.On your precut ultra for wintertime with doors, since you have hot knife cut out the fabric is there any reason I would need to do any sewing anywhere beside the ridge line and the various pull outs?

How long would you estimate a very experienced seamstress would take just to do a flat-felled/French seam hybrid on just the ridge-line?

hybrid?

when the doors are closed are they further off off the ground than the sidewalls? If so. about how far are they off of the ground when the doors are closed?

Thanks.

paul

Is it better to use SilNet or SeamGrip for the Membrane Sil Poly?

I had two questions with regards to this article. When bonding silnylon in this fashion, the peel strength is very weak, correct(not that this matters, more curiosity)? Should the edges be sealed after bonding to ensure that a peel is not started? Also, wouldn’t the correct statement be that when bonding the reinforcement to the substrate that the fabric grains should be aligned so that they stretch identically? I believe the wording you have is “same direction as intended force” which contradicts my previous statement in most applications.

When sewing loops on a tarp it is also important it is sewn directly on the rolled hem as well as on the reinforcement patch. The rolled hem is much stronger and takes a lot of the stress and to some degree acts as a frame pulling the fabric out to the intended shape.

I used this method on a diy megatarp knock off but I sewed the perimeter for insurance and it did well so far.

Great write up. When you get the rig for testing to breaking set up, I’d be interested to see what (if any) difference different thread/needle size combinations make as well.

Will this work okay on SilNylon?

If I remember right from stage rigging classes wind can exert 12 pounds per square foot at 60mph, 6 pounds at 30mph. Wind gusts hitting one side of a 12×10 tarp can equal 720 pounds of force.

Would you recommend this approach to the normal (1.1 oz) Silpoly fabric also? Thanks!

@shawn There’s less bias stretch with the PU4000, so I don’t think the chance of an issue is quite as high. That being said, it wouldn’t hurt to use this method and you would definitely save a bit of weight compared to using the more bulky HD300.

Thanks for the article. I recently purchased a tarp kit with sillily PU4000. Do you think that a double layer of this fabric would be needed as it is with the UL silpoly? Do you think that I can save some weight by using this method instead of the hyper D? Thanks again,

Glad we could help John. I agree it’s a bit counter intuitive, but after you think about it things make sense. The extremes tend to illustrate the point and in this case the problem of mismatch doesn’t seem to crop up until you start working with these very thin, ultralight coated fabrics.

Let us know if you need anything before your build. Thanks!

Nice write up and good information. I don’t think I’m going to be able to afford making my own tarp until next year, but will be bookmarking this page to refer back to. I can see how using a tougher material than the tarp actually could end up hurting the situation, but I admit I’ve thought that way for a while also. It seems logical that a stronger, less stretchy material would “reinforce” the tie-outs. But I see now that under stress, those areas could still have problems because something has to give. I like the idea of bonding to the tie-out, a reinforcement material to give a stronger bond.

Kudos! I can’t wait to build my own tarp.

John

Comments will be approved before showing up.

Baptiste

January 22, 2021

Hi,

Super useful information

Would you recommend this approach for silpoly PU 4000?

And regarding the direction of the patch you cut, are you trying to line up the warp and weft of both pieces of fabric? Or with an angle of 45 degrees?

Thanks!